In the automotive industry, the selection of materials for car parts is paramount in defining vehicle performance and quality. Aluminum car parts have surged in popularity, driven by their myriad advantages for manufacturers and consumers alike.

Is Aluminum Good For Car Parts?

Aluminum has become a favored material for car parts in the automotive industry due to several compelling reasons. Let’s delve into some of these factors.

Weight Savings

One of the key attractions of aluminum car parts is its ability to significantly reduce the weight of vehicles. For example, the 2015 Ford F-150 featured a body that was 95% aluminum, making it 700 pounds lighter than its predecessor. This weight reduction is possible because aluminum is one-third the weight of steel. Despite its lighter weight, aluminum alloys can be engineered to provide strength comparable to steel, making them a versatile option for auto parts.

Versatility

Aluminum offers a range of alloys with different physical properties, making them suitable for various automotive applications. Alloys in the 6000 and 7000 series, known for their strength properties, can be heat-treated to enhance their durability. Alloys like 6082 and 7003 are commonly used in rear headers, IP beams, ABS blocks, and other components. Casting alloys such as the B390 alloy are tailored for engine blocks, valve bodies, and piston housings, showcasing the material’s versatility in automotive design.

Improved Safety

Larger auto parts have the advantage of absorbing more crash energy upon impact, thereby enhancing vehicle safety. Aluminum’s lightweight nature allows for the creation of larger parts compared to steel, leading to improved crash performance. With aluminum’s ability to absorb twice as much energy as steel and crumple predictably, occupants benefit from a greater buffer during collisions, protecting the vehicle’s interior.

Environmental Benefits

In addition to safety advantages, aluminum car parts offers environmental benefits. Lighter vehicles require less energy to operate, leading to reduced CO2 emissions in aluminum-intensive vehicles. Gas-powered cars experience improved fuel efficiency, while electric vehicles can benefit from reduced battery usage and extended ranges. Moreover, aluminum is infinitely recyclable, allowing for sustainable practices as it can be recycled multiple times without degradation.

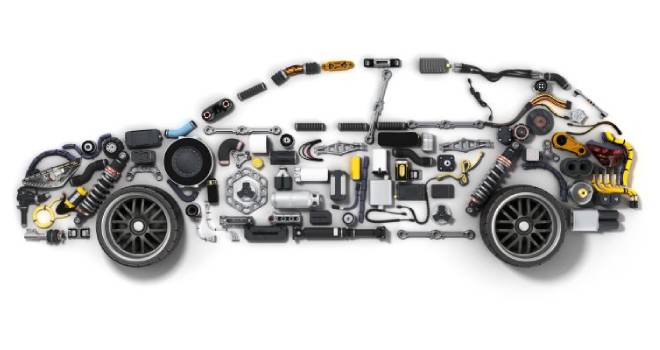

What Parts Of A Car Are Made Of Aluminum?

Aluminum is a versatile material extensively utilized in automotive manufacturing for various components due to its advantageous properties beyond just lightweight. Here’s an overview of the aluminum car parts and the reasons behind their selection:

Aluminum Engine Block

An engine block made of aluminum offers not only weight savings but also superior heat dissipation properties, which can enhance engine performance and longevity. The material’s corrosion resistance and ability to dampen vibrations contribute to overall engine efficiency.

Aluminum Wheel

An aluminum wheel is not just lightweight but also known for its excellent heat dissipation characteristics, which can help prevent brake overheating and improve braking performance. Additionally, these aluminum parts offer design flexibility, allowing for intricate and stylish wheel designs.

Aluminum Transmission Housing

A transmission housing made of aluminum provides a good balance between strength and weight, contributing to improved fuel efficiency and reduced energy losses in the transmission system. Aluminum’s thermal conductivity helps in maintaining optimal transmission temperatures.

Aluminum Body Panel

An aluminum body panel offers more than weight reduction; it also provides superior corrosion resistance, which can prolong the vehicle’s lifespan and maintain its appearance over time. The material’s formability allows for complex shapes, enhancing aerodynamics and design options.

Aluminum Suspension System

An aluminum suspension component not only reduces unsprung weight but also offers excellent stiffness-to-weight ratios, improving handling and ride comfort. The material’s damping characteristics can enhance the vehicle’s stability and responsiveness on various road surfaces.

Aluminum Interior Trim

An aluminum interior trim component adds a premium look and feel to the vehicle’s interior while also offering durability and resistance to wear and tear. The material’s ability to be textured and finished in different ways allows for customizable and high-quality interior designs.

Reflector and Heat Shield

In headlights and taillights, aluminum is used for its reflective properties, aiding in maximizing light output and visibility. The material’s thermal management capabilities make it ideal for heat shield applications, ensuring the longevity and performance of lighting components.

Common Grades of Aluminum for Car Parts

1100 Series Aluminum For Car Parts

This series aluminum , known for its corrosion resistance and formability, is often used in car body panels, trim pieces, and interior decorative elements due to its ease of fabrication and finishing.

4032 Aluminum Car Parts

4032 aluminum parts, with its high thermal conductivity and wear resistance, is commonly employed in pistons for engines, where components experience high temperatures and mechanical stress.

3105, 3003, and 3004 Aluminum

These alloys find applications in automotive sheet metal, such as body panels, hoods, and roofs, thanks to their formability, corrosion resistance, and moderate strength, essential for shaping durable exterior parts.

2024 Aluminum Parts

Recognized for its high strength, 2024 aluminum parts is utilized in structural automotive components like chassis parts and other structural elements where toughness and strength are critical.

5005, 5182, 5083, 5052, and 5251 Aluminum

These aluminum are favored for manufacturing automotive body panels, fuel tanks, and structural parts, offering a blend of strength, formability, and corrosion resistance required for various exterior and structural applications.

6022, 6061, 6181, and 6016 Aluminum

These high-strength alloys are commonly found in chassis parts, suspension systems, and crash structures due to their exceptional strength-to-weight ratio, machinability, and weldability, making them ideal for critical automotive applications.

7046 and 7003 Aluminum

These alloys, designed for high-strength applications, are often used in automotive wheels, frames, and suspension components, providing superior strength, formability, and weldability for parts subjected to significant mechanical loads and stress in vehicles.

Find Best Aluminum For Automotive

As a leading manufacturer of aluminum products, equipped with cutting-edge technology and extensive industry expertise, we specialize in providing top-tier aluminum solutions for the automotive sector. Whether you require premium aluminum car parts or raw aluminum materials tailored for automotive applications, we offer unparalleled quality and precision. With our commitment to excellence and years of experience, we ensure that you receive the finest aluminum products optimized for automotive performance and durability. Partner with us for your aluminum needs in the automotive industry and experience the difference that superior craftsmanship and expertise can make.