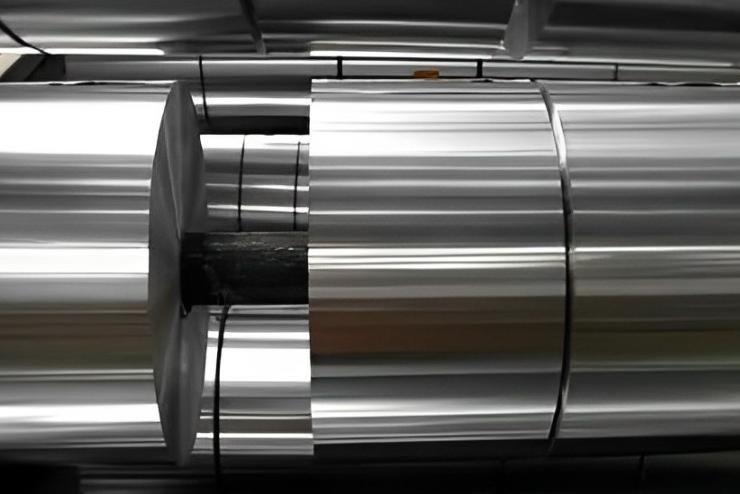

Aluminum Foil

Aluminum Foil Types

We sell transformer aluminum foil, foil for product packaging, insulation, and transportation.

Transformer

Transformer aluminum foil offering excellent electrical conductivity and heat dissipation properties essential.

Packaging Foil

With barrier properties against light, moisture, and contaminants, it can be used for various packaging applications.

Household Foil

Our household aluminum foil includes 1235 aluminum foil, 3003 aluminum foil, and 8011 aluminum foil.

Decorative Foil

Decorative aluminum foil can be used for applications such as crafts, interior design, and packaging.

Pharmaceutical

The main grades of aluminum foil for pharmaceutical use include 1235, 8011, and 8021 aluminum.

Electronic Foil

Aluminum foil can be used in the production of various electrical and electronic equipment.

Venetian Blind Foil

Our Venetian blind aluminum foil includes 3104, 5052, and 3E05 aluminum.

Cable Aluminum Foil

Aluminum foil for cables can not only serve as a protective outer sheath for cables but also provide signal shielding.

Aluminum Foil Supplier

We offer a wide range of grades, including 1050, 1060, 1100, 3003, 3104, 5052, 6061, 8011, and 8021 aluminum foil. These grades cater to various applications across different industrie

Aluminum Foil for Sale

- Aluminium Foil For Transformer Winding

- Brazing Aluminum Foil

- Deep processing Aluminum Foil

Transformer Aluminum Foil

Our aluminum foil offerings for transformer winding encompass grades 1050/1060/1070/1350-HO(O). The foil provided is pristine, devoid of dents, surface irregularities, waviness, scale, or any flaws. Both the surface and edges exhibit a flawless finish, absent of any burrs or imperfections, conforming precisely to a rounded edge standard.

Aluminum Foil Specifications

| Aluminum Foil Grade & Temper | 1050/1060/1070/1350-HO(O) |

| Thickness/mm | 0.2-3.0 mm |

| Width/mm | 20-1350 |

| Inner Diameter/mm | Customizable |

| Conductivity Number/% IACS | ≥61 |

| Elongation/% | 20 |

| Resistivity number (Ω·mm² /m) | ≤0.027548 |

| Tensile strength/Mpa | >60 |

| Density in 20°C (kg/cm3) | >60 |

For Transformer Winding

The versatility and reliability of our aluminum foil extend to various types of transformers, including electrical transformers, distribution transformers, and cast resin transformers. It meets diverse needs in electrical transformers—optimizing space, boosting efficiency, and ensuring durability.

- Compact Size and Lightweight Properties: Aluminum foil for winding offers a compact size and lightweight properties, ideal for efficient transformer design.

- Excellent Insulation and Flame Retardancy: It provides excellent insulation and flame retardancy, ensuring safe and reliable transformer operation.

- Eco-friendliness and Resistance: The foil is eco-friendly and resistant to partial discharge and moisture, enhancing longevity and performance.

- Dependable Operation and Noise Reduction: It promotes dependable operation, noise reduction, and cost-effective maintenance in transformer systems.

Request a Quote

If you require any assistance, we kindly request you to complete the form provided below. Our dedicated sales team will promptly reach out to you, and rest assured, you can expect a response to your inquiry within a maximum of 12 hours.

+86 0411-8683 8503

Aluminum Land available from 00:00 – 23:59

Address :Room A306, Building#12, Qijiang Road, Ganjingzi

Email : info@goseamarine.com