Automotive Grade Aluminum

Car Aluminum

Aluminum Car Parts

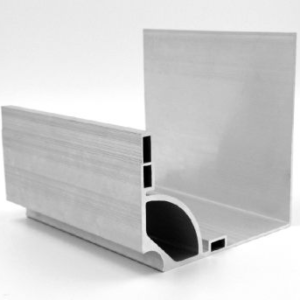

Special-purpose car aluminum profiles (utilizing 6061, 6005A, and 7005 aluminum alloys) are widely used in specialized aluminum car parts

Automotive Aluminum Profiles

High-speed train carriage external framework, reinforced structure, fixed structure. Dimensions can be customized

Battery Bracket for Energy Vehicles

The main material used for securing the electric vehicle battery is aluminum alloy, known for its durability, and strength。

Automotive Crash Structure

Suitable for Manufacturing Aluminum Automotive Crash Safety Structures (Automotive Aluminum Crash Beams, Internal Structural Frameworks, etc.

Car Body Profiles

Mainly used in high-speed train carriages.

Conductive Rail Profiles

The use of conductive rail profiles in railway transportation

Train Side Panel Profiles

These profiles are lightweight, durable, and have excellent structural integrity.

Our Automotive Aluminum for Sale

The weight reduction in specialized vehicles is of great significance for energy conservation, reducing operating costs. Our aluminum profiles are highly corrosion-resistant, have high strength-to-weight ratio, and good formability, making them popularly applied in specialized vehicles both domestically and internationally.

Special-purpose automotive aluminum profiles (utilizing 6061, 6005A, and 7005 aluminum alloys) are widely used in specialized automotive components or decorative assemblies for tankers, trailers, refrigerated trucks, water trucks, and other specialized vehicles. These profiles exhibit excellent mechanical properties and some profiles also possess good fatigue performance.

Aluminum For Automotive

What aluminum is used in the automotive industry?

- 6000 Series Aluminum: This car aluminum is known for its excellent combination of strength, formability, and corrosion resistance. It is often used for body panels, chassis components, and structural parts in automotive applications.

- 5000 Series Aluminum: With high strength and good corrosion resistance features, 5000 series aluminum for automotive is commonly used in applications where strength and durability are crucial, such as in the manufacturing of wheels and structural components. The most popular alloys are the 5052, 5083, and 5454 aluminum alloys.

- 2000 Series Aluminum : 2000 series automotive aluminum exhibits excellent strength and heat resistance, making it suitable for applications such as engine blocks, cylinder heads, and other high-stress components in automotive engines.

- 7000 Series Aluminum: offers exceptional strength and toughness, making it suitable for applications that require high performance and structural integrity. It is commonly used as aluminum car parts like suspension components, crash structures, and other safety-related parts.

- 3000 Series Aluminum: Moderate strength, good formability, and excellent corrosion resistance. 3000 series automotive aluminum is often used in automotive heat exchangers, radiator tubes, and other cooling system components.

Types of Auto Alumium

Auto Aluminum Mechanical properties

| Alloys | State | Yield Strength(Mpa) | Tensile strength(Mpa) | Percentage of elongation (%) |

| 5083 | O/H111, H112 | >125 | 270-350, >275 | >15, >12 |

| 5454 | O/H111, H112, H32 | >85, >125, >180 | 215-275, >220, 250-305 | >17, >8 |